Industry Variations: Price Transparency and Market Segmentation

In Google’s global sourcing data, searches for “Factory Price squash court” have increased by 90% in the past 18 months, while localized searches for “Squash court location” have become the fastest-growing long-tail keyword. These two sets of data outline a two-track transformation in the squash industry: on the one hand, upstream manufacturers are seeking a new balance between cost and quality; on the other hand, downstream consumption is matching space and foot traffic with unprecedented precision.

Standardized prefabrication is rewriting the meaning of “factory price.” When a factory in Guangdong quotes a price to a Swedish customer, the price list is broken down into more than 200 options—from the anti-glare coating grade of the glass back wall to the rebound coefficient range of the elastic padding under the floor. The widespread adoption of this “menu-style pricing” means that “factory price” is no longer synonymous with low price, but rather value segmentation driven by transparency. A North American squash court distributor pointed out, “Now, customers are comparing price lists from different Chinese factories not based on the total price, but on the technical parameters and corresponding prices of specific modules. This forces manufacturers to achieve the best global cost-performance ratio for certain niche components.”

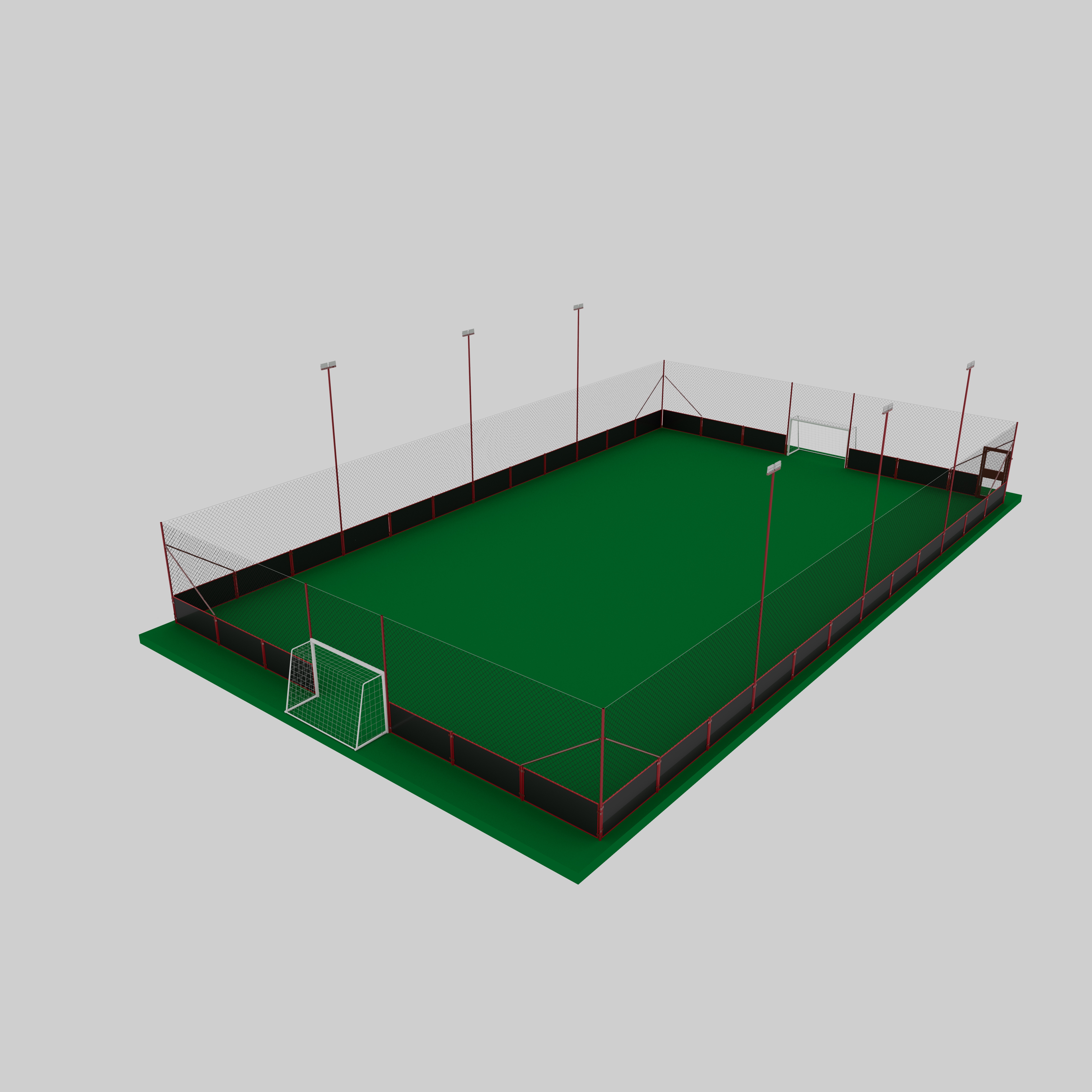

Factory Direct Glass Squash Court for Club and Sports Center Projects

The Geographical Characteristics of Hot-Selling Logic

“Hot-selling squash courts” present vastly different appearances on different continents. In East Asian and Western European cities where land resources are scarce, vertically stacked “double-unit” courts have become the preferred choice for commercial clubs, with hourly revenue per square meter 40% higher than traditional single-story designs. Meanwhile, in the suburbs of the Middle East and North America, “squash+” complexes integrating leisure areas, spectator bars, and children’s activity corners are becoming new community landmarks, with their core profitability shifting from single venue fees to diversified membership services.

This differentiation in hot-selling products directly drives flexible production reforms on the manufacturing side. A professional manufacturer in Zhejiang has achieved “mixed-flow production”—on the same assembly line, depending on order demand, alternately producing moisture-proof wall panel systems suitable for high-humidity areas and high-temperature resistant ventilated integrated roofs suitable for desert regions. This signifies a shift in export competition from large-scale standardization to agile supply chain responsiveness based on small-batch, multi-batch operations.

LDK Indoor Squash Court Double Player Squash Court Squash Sports Venue

How Spatial Algorithms Are Reshaping Court Location Selection

Decisions regarding “squash court locations” are moving from relying on experience and intuition to data-driven, precise calculations. Professional location software accesses publicly available urban data streams, analyzing the following within a 5-kilometer radius of a target area: the density distribution of high-income individuals aged 25-45, the saturation of similar sports facilities (such as badminton and tennis courts), traffic congestion indices in the evenings and weekends, and even the number of nearby cafes and gyms.

A prime example is the situation in London’s Canary Wharf. A club used algorithms to discover a significant gap in demand for sports facilities in the financial district on Friday evenings. Based on this, they designed a “Friday Night Lightning Station” model, splitting squash court bookings by the hour and providing light meals and social spaces, increasing utilization from less than 30% to 95% for that period. This reveals a new trend: the future value of a court will be determined not only by building materials but also by the precision with which it is embedded in the city’s temporal and spatial sequence.

Professional Squash Court System for Club and Sports Center Projects

Technological Convergence: From Sports Containers to Health Data Centers

Cutting-edge courts are becoming terminals for collecting biomechanical data. An experimental court developed by Loughborough University in the UK in collaboration with a manufacturer uses harmless millimeter-wave radar and pressure sensors embedded under the sidewall glass and floor to non-invasively capture athletes’ heart rate changes, shot force distribution, and thermal maps of movement trajectories. This data, after being anonymized, can be used to optimize court design (such as improving ventilation areas) and generate personalized training reports for players.

This “invisible intelligence” is the next competitive barrier. It requires manufacturers to integrate architectural acoustics, material sensing, and edge computing technologies across disciplines. It is foreseeable that future procurement contracts will include data interface protocols and secure transmission

Custom Glass Squash Court Solution for Commercial Gymnasiums

A Dual Interpretation of Sustainability

Sustainability is being practiced in two ways in the squash industry. At the materials level, using recycled glass for the back wall and replacing some maple flooring with bamboo fiber composites have become standard features for green certification in high-end projects. At the operational level, a “staggered sharing” model is emerging in Europe—community squash courts used for school physical education classes during the day and open to the public in the evenings and on weekends are efficiently scheduled through a digital reservation system, with public funding subsidies directly linked to the facility’s daily utilization rate.

From modular prefabrication in factories and algorithmic addressing using geographic information to data-driven operation, the modern squash court has evolved into a complex product integrating advanced manufacturing, location science, and health management. Its development trajectory clearly demonstrates that the international competitiveness of sports facilities increasingly depends on their deep ability to integrate physical manufacturing with digital intelligence and respond to specific spatial and social scenarios. For industry observers, while focusing on the design of the next “blockbuster” court is important, understanding the underlying logic of cost transparency, spatial algorithms, and sustainable operation models is crucial to grasping the true pulse of global market changes.

Publisher:

Post time: Feb-03-2026