How Technological Revolution Reshapes the Business Ecosystem of a Sport

While pickleball has swept through North American communities with 36 million participants, a silent materials revolution is unfolding in the equipment industry. Pickleball rackets, once considered toys for amateurs, are now at the forefront of innovation at the intersection of materials science and sports engineering.

The Rise of Carbon Fiber: How 16mm Thickness Defines a New Standard

“For the past two years, competition in the high-end racket market has revolved entirely around carbon fiber,” points out a materials expert at a US sports lab. “The emergence of 16mm thick carbon fiber rackets marks the beginning of a ‘micrometer-level war’ in this competition.” This specific thickness is no accident—it balances power transfer efficiency with shot control, allowing intermediate players to achieve near-professional shot feedback.

Market data shows that sales of carbon fiber rackets priced between $150 and $250 increased by 210% year-on-year in 2023. Behind this growth lies the precise application of materials science: a 16mm thickness combined with aerospace-grade carbon fiber weaving technology allows the racket to maintain a weight below 240 grams while withstanding a hitting frequency of over 8000 times per minute.

The Industry-Wide Linkage Effect from Equipment to Infrastructure

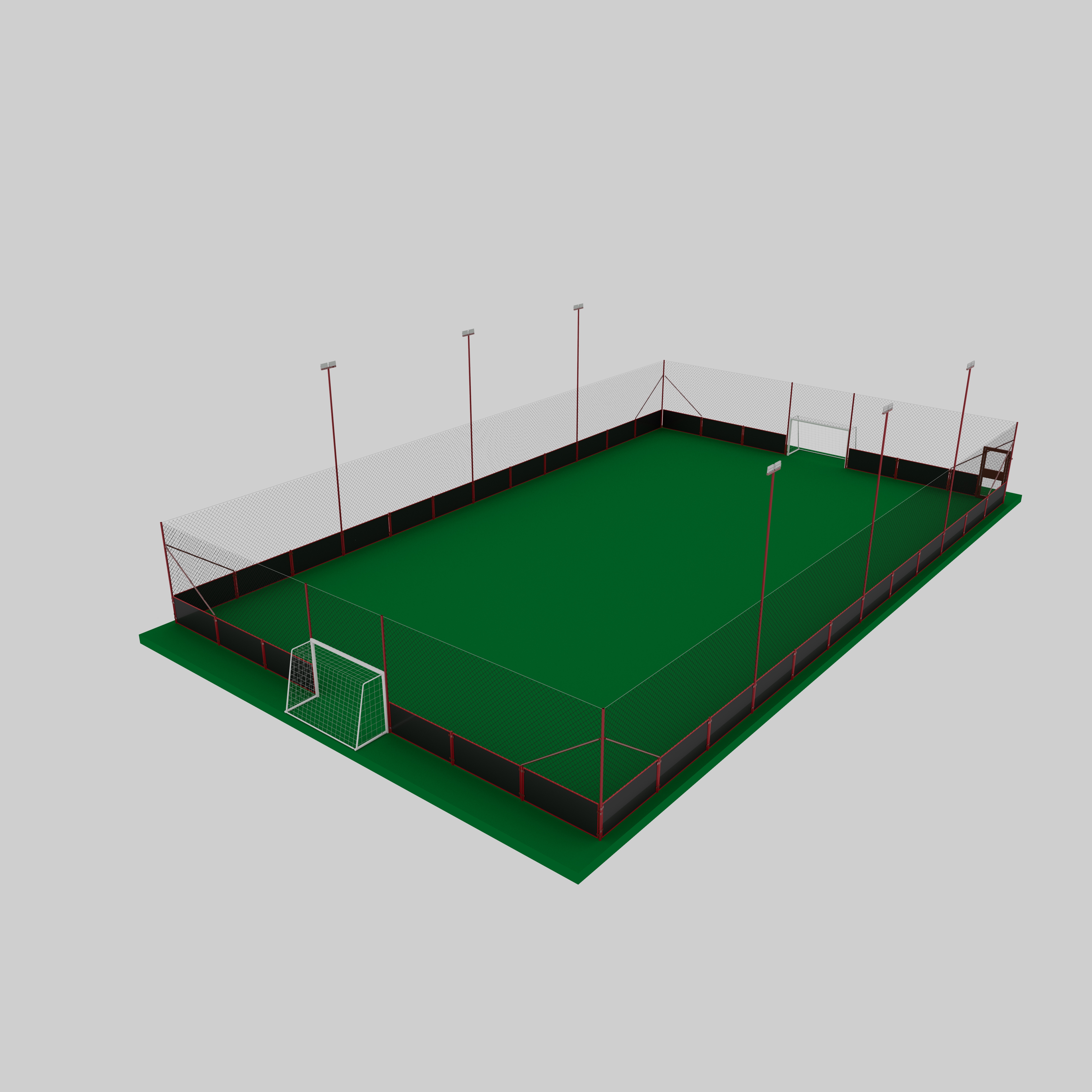

The specialization of racket technology is creating a chain reaction. “When we design Peak courts for clubs, owners now specifically inquire about the impact of surface materials on the performance of carbon fiber Peak rackets,” said the international project director of a Shenzhen-based sports facilities manufacturing company. “They need to ensure that the surface hardness matches the performance characteristics of high-end rackets.”

This demand has spurred new service models. As a manufacturer providing both Peak ball and paddle tennis court solutions, the company has found that over 60% of its court consultation clients also inquire about equipment selection advice. “We are transforming from a mere space builder into a sports experience designer—ensuring both that the court meets USAPA standards and that the lighting system can clearly capture the high-speed trajectory of the carbon fiber rackets.”

How Professional Certification Becomes a Market Dividing Line

With the USAPA tightening its certification standards for professional tournament rackets, compliance is becoming a market dividing line. “The new 2024 regulations require rackets thicker than 16mm to pass more stringent deformation tests,” revealed a technical director at a certification body. “This directly differentiates high-end products from ordinary carbon fiber rackets.”

The rise in professional standards is reshaping the supply chain. A manufacturer that produces carbon fiber rackets for multiple brands confirmed that their production line has added three quality control steps specifically for 16mm models. “Professional players are very sensitive to weight differences as small as 0.1 grams, which forces us to raise manufacturing precision to a whole new level.”

High quality Cold pressed Pickleball Racket

The Next Step in Intelligence: Data-Driven Equipment Evolution

Industry observers point out that the next evolutionary direction for Peak rackets is already evident: smart rackets with built-in motion sensors will be widely available in the third quarter of 2024. These data-driven devices, capable of recording shot angles, spin speeds, and power distribution, will not only transform training methods but may also influence court design standards.

“As smart rackets become more widespread, the definition of an ideal court may incorporate a new dimension: ‘data-collection friendliness,’” added the aforementioned director of a Shenzhen-based company. “We are already developing a court management system compatible with various sensor data, which is precisely the essence of a one-stop solution—providing a complete technological loop from racket to court.”

From community parks to professional arenas, this small racket is driving the entire industry’s upgrade trajectory. When the texture of carbon fiber meets the court markings under the same technical standards, Peakball has quietly transformed from a recreational activity to a professional sport.

Publisher:

Post time: Dec-05-2025